Engineers Confront Ebola Epidemic

The real-life global problem: Ebola outbreak. The challenge: to develop low-cost, technology-driven solutions to meet the tremendous risks posed by the Ebola crisis.

Realizing the urgency to control the outbreak, in October the deans at Columbia Engineering and the Mailman School of Public Health sponsored a rapid-fire design challenge to confront the Ebola crisis. The idea behind the challenge was to not only develop lowcost, real-time solutions, from concept to deployment, but also engage the Columbia community—from all disciplines—to take action and work together on this critical global issue.

“Engineers create solutions that address global challenges,” said Dean Mary C. Boyce. “There is an urgent need for innovative, cost-effective solutions to de-escalate this public health crisis, and so we encouraged our students and faculty from across the University to concentrate their creative energies on working on innovations to ameliorate this situation.”

Eleven teams of students—undergrads and grads—and faculty from the Engineering School; Mailman; School of International and Public Affairs; Columbia College; and the Graduate School of Architecture, Planning and Preservation; among others—worked on practical designs or rough prototypes to help victims, their families, and healthcare workers.

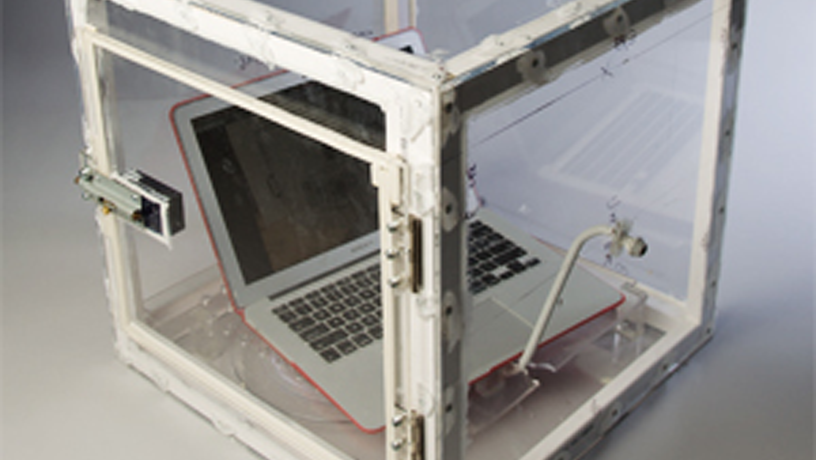

This low-cost, portable decontamination chamber will allow for on-site decontamination of electronics from laptops to cell phones.

(Photo by Jeffrey Schifman)

The teams worked 24/7 in brainstorming sessions and, in less than two weeks, developed and presented their proposals to a panel of leading public health specialists and engineers, including Dean Boyce, Mailman Dean Linda Fried, Mechanical Engineering Chair Jeffrey Kysar, and Mailman’s W. Ian Lipkin, an authority on epidemiology and outbreak response. The panelists helped shape the concepts, also garnering feedback from infectious disease experts from the World Health Organization, Centers for Disease Control and Prevention, and Médecins Sans Frontières. The goal: to help fund the design of a viable prototype and pursue more support for actual deployment and use.

“What a great partnership this has been,” said Boyce during the final presentations held at Mailman in December. “It has been great to be able to light the fire under so many people to come together, to work on different and very creative and innovative solutions so quickly. It’s impressive how the constructive feedback we have been giving has been embraced. The designs have gotten better.”

Three of the solutions proposed were being considered for funding in the USAID Fighting Ebola Grand Challenge: a low-cost pigmented bleach solution, a decontaminating bleach foam, and a portable decontamination chamber. (The pigmented bleach solution won USAID support.) Other participants developed an Ebola-specific protective containment suit and a 3-in-1 cot system.

The design challenge itself made headlines, including in Fast Company, NPR, The New Yorker, and The Washington Post. And some of the teams’ ideas are already being used or are in the midst of deployment. The Fire Department of the City of New York, after testing the pigmented bleach solution in early December, has incorporated it into its HazMat unit decontamination protocol, spraying surfaces such as ambulance doors and personal protective equipment suits.

Professor Ponisseril Somasundaran and his team of post-docs are testing and further developing their innovative bleach foam for deployment.

Professor Ponisseril Somasundaran and his team of post-docs are testing and further developing their innovative bleach foam for deployment.

(Photos by Jeffrey Schifman)

The teams worked 24/7 in brainstorming sessions and, in less than two weeks, developed and presented their proposals to a panel of leading public health specialists and engineers, including Dean Boyce, Mailman Dean Linda Fried, Mechanical Engineering Chair Jeffrey Kysar, and Mailman’s W. Ian Lipkin, an authority on epidemiology and outbreak response. The panelists helped shape the concepts, also garnering feedback from infectious disease experts from the World Health Organization, Centers for Disease Control and Prevention, and Médecins Sans Frontières. The goal: to help fund the design of a viable prototype and pursue more support for actual deployment and use.

“What a great partnership this has been,” said Boyce during the final presentations held at Mailman in December. “It has been great to be able to light the fire under so many people to come together, to work on different and very creative and innovative solutions so quickly. It’s impressive how the constructive feedback we have been giving has been embraced. The designs have gotten better.”

Three of the solutions proposed were being considered for funding in the USAID Fighting Ebola Grand Challenge: a low-cost pigmented bleach solution, a decontaminating bleach foam, and a portable decontamination chamber. (The pigmented bleach solution won USAID support.) Other participants developed an Ebola-specific protective containment suit and a 3-in-1 cot system.

The design challenge itself made headlines, including in Fast Company, NPR, The New Yorker, and The Washington Post. And some of the teams’ ideas are already being used or are in the midst of deployment. The Fire Department of the City of New York, after testing the pigmented bleach solution in early December, has incorporated it into its HazMat unit decontamination protocol, spraying surfaces such as ambulance doors and personal protective equipment suits.

Jason Kang ’16SEAS, who helped develop the pigmented bleach, said the chance to come up with an engineering solution in real time with real impact is what becoming an engineer is all about. “I was extremely excited when I saw that Columbia was holding this challenge,” Kang said. “I believe challenges with real-world applications will greatly improve the culture of innovation and social impact at Columbia.”

Top row, clockwise from left: Dr. Chris Aston of Environmental Health & Safety at Columbia University (left) and W. Ian Lipkin of Mailman School of Public Health during design challenge presentations; this team is currently testing their prototype and is aiming to deploy the decontamination unit for use in West African hospitals; Engineering Dean Mary C. Boyce provides feedback and advice to design challenge participants; Engineering students present their design for a low-cost, disposable PPE suit. (Photos by Timothy Lee Photographers)

Top row, clockwise from left: Dr. Chris Aston of Environmental Health & Safety at Columbia University (left) and W. Ian Lipkin of Mailman School of Public Health during design challenge presentations; this team is currently testing their prototype and is aiming to deploy the decontamination unit for use in West African hospitals; Engineering Dean Mary C. Boyce provides feedback and advice to design challenge participants; Engineering students present their design for a low-cost, disposable PPE suit. (Photos by Timothy Lee Photographers)

Bottom row, from left: 3D model of student team’s design of a portable cot (Image courtesy of Marisol Rodriguez); students behind the portable cot project, (upper row) Lauren Cardenas, Ankita Gore, and Marisol Rodriguez, and (lower row) Sydney Garay, Mimoun Delmar, and Sigal Winfield (Photos by Jeffrey Schifman); W. Ian Lipkin, a leading authority on epidemiology and outbreak response (Photo by Timothy Lee Photographers)

Engineering Professor Ponisseril Somasundaran and his team of postdocs Jun Wu and Partha Patra called the entire experience a “great journey,” and are testing and further developing their innovative bleach foam for deployment. The foam decontaminates a larger area, deposits uniformly on different types of surfaces, provides enough contact time to kill the virus, and better adheres to contaminated surfaces.

Collaborating was essential to the team who designed the portable decontamination chamber, a low-cost unit that will allow for on-site decontamination of electronics, from computer monitors to cell phones. According to Kay Igwe, a first-year master’s student in electrical engineering, meeting new people from different disciplines was one of the best parts about the design challenge. “It is interesting to see how people think. There are things the electrical engineers do not think of that the biomedical engineers do, or that the mechanical engineers may have considered, but others did not,” she said.

SEAS and Mailman advisors agreed on the urgent need for the portable decontamination chamber and are currently helping the team test their prototype, aiming to deploy the unit for use in West African hospitals including Columbia’s satellite site in the region.

The challenge fell right in the middle of midterms, but, notes Lipkin, even that did not deter student interest. “They really want to do something,” he said. “It’s really great.” Added Boyce, “I am impressed with what they have been able to come up with in such a short amount of time.”

This first-ever real-time design challenge demonstrated that engineering design and innovation have global impact, and underscored the critical need for engineers. So much so that both deans have stated they intend to sponsor more of these challenges in the future.

Their rewards and benefits are made evident by student enthusiasm, typified by Ritish Patnaik ’16SEAS, who said, “We’ve definitely challenged each other respectfully to produce the best ideas and methods to make our protective suit a success. I really hope we have more challenges like this in the future.”