Changing the Rules of the Modeling Game

Imagine a world where AI merges with mechanics to create highly accurate models and simulations that will enable the materials, devices, and structures of the future

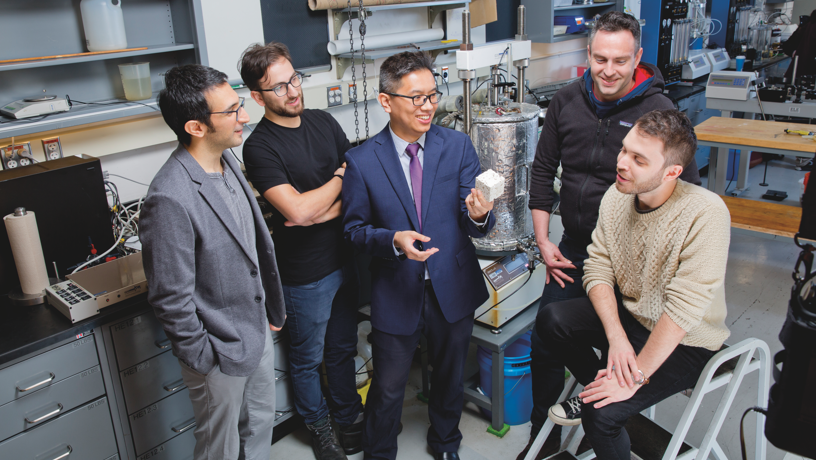

Sun with students (from left to right) Bahador Bahmani, Massimo Carloncelli, Eric Bryant and Nikolaos Napoleon Vlassis in his lab.

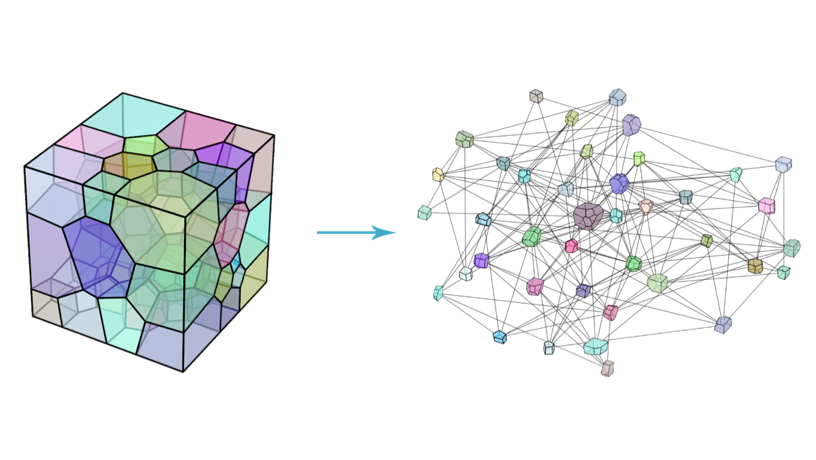

Schematic of a polycrystal and the corresponding weighted graph used to train AI to solve mechanics problems.

Whether assessing the safety of nuclear waste or verifying the robustness of an aircraft carrier, our built world relies on models with such detailed understanding of materials that they can accurately predict performance far into the future.

And as new materials and properties are discovered and created, the onslaught of new data requires models that can keep pace with discovery, taking into account not just properties from the micro to the macroscale, but how these properties work together.

Enter reinforcement learning (RL), a subset of machine learning. It uses similar techniques to empower an agent to optimize its performance based on a system of incentives and rewards. Big tech companies and the financial industry rapidly adopted RL. So far, it has not been widely used in civil engineering modeling processes to predict material response and failure—a situation that led Steve WaiChing Sun, assistant professor of civil engineering and engineering mechanics, to ask why.

“You can think about much of a scientific process as a game with a set of rules,” Sun says. “By capturing that process in RL, we can afford to fail hundreds of times in order to succeed.”

Where the “rules of the game” are universal principles of mechanics, Sun’s methodology involves an agent that repeatedly generates new models that obey these principles while accounting for relationships among data and even the hidden physics in microstructures. Through continuous play, the agent learns how to better balance the need to explore and exploit different hypotheses. This increasing knowledge of materials enables the agent to determine how to choose a sequence of decisions that will optimize the model scores used to measure the accuracy and speed of forecasting.

Sun’s approach reduces a modeler’s lengthy process of trial and error from a matter of months to a matter of hours by using AI to ferret out the best theories from the millions of hypotheses represented.

His methodology could accelerate the development of models to predict material behaviors in extreme environments. It may also help create more realistic digital twins, virtual representations of real-world objects and systems ranging from cell phones to oil reservoirs, that analyze various life-cycle scenarios with minimal physical prototypes.