Manipulating Sound with Building Blocks

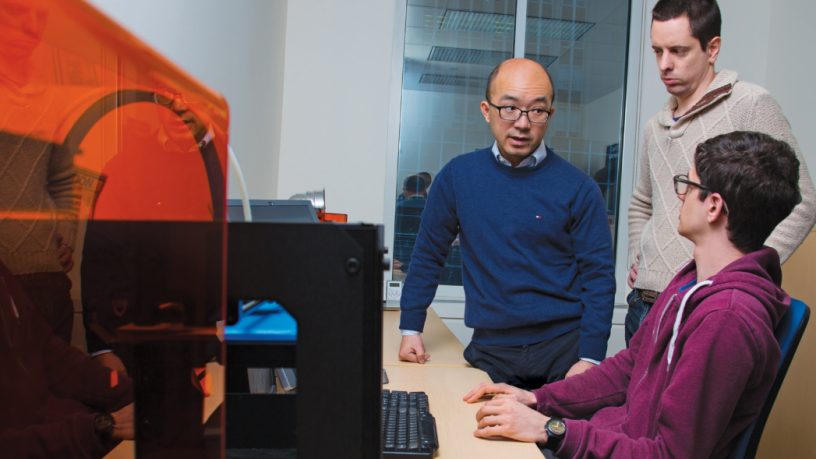

Changxi Zheng’s 3D-printed objects are a playful way to display the possibilities of embedding data through sound.

Acoustic voxels, the playground of Computer Science Assistant Professor Changxi Zheng, are small, hollow, cube-shaped chambers through which sound enters and exits. Like Legos, the voxels can be connected to form an infinitely adjustable, complex structure. Because of their internal chambers, they can modify the acoustic filtering property of the structure. Changing their number and size or how they connect alters the acoustic response.

Acoustic Voxels: Computational Optimization of Modular Acoustic Filters

Working with colleagues at Disney Research and MIT, Zheng and his team have developed algorithms to computationally optimize design for manipulating acoustic propagation in a wide variety of objects, such as automobile mufflers and musical instruments. The technology could also be used to create unique, hard-to-counterfeit identification tags for works of art or jewelry, opening the door to encoding product and copyright information into the object's very form, Zheng said.

The researchers were inspired by Zheng's prior work using computational methods to design and 3D print a zoolophone, a xylophone-type instrument with keys in the shape of zoo animals. The zoolophone represented fundamental research into vibrational sound control, leveraging the complex relationships between an object's geometry and the surface vibrational sounds it produces when struck.

The team designed new algorithms that take as input the overall geometry of the object to be created and the sound characteristics desired. "It's a much more intelligent form of computeraided design," Zheng said. "You tell the computer what kind of sound you want, and the system decides what the internal shape should be by searching and finding a valid structure and architecture composed of acoustic voxels."

The shape of the ultimate object can be almost anything: To demonstrate the acoustic tagging, Zheng's team 3D printed a toy octopus that, when processing white noise generated by an iPhone app the group had designed, generated a sound that was read and analyzed by the app.

"In this aspect of our work, we're trying to exploit the increasing power of the 3D printer," Zheng explained. "Its ability to manufacture complex shapes at low cost opens the door for us to leverage that complexity to engineer better acoustics."

Longer term, Zheng is looking to develop relationships with industry; he mentioned that some startups in China had expressed interest. His group is also collaborating with MIT's mechanical engineering department to design underwater acoustic devices. "We are investigating some of the intriguing possibilities of ultrasonic manipulation, such as cloaking, where sound propagation can be distorted to hide objects from sound waves. This could lead to new designs of sonar systems or underwater communication systems. It's an exciting area to explore."